June 24, 2025

BC Crane Safety Newsletter

SUMMER 2025

Introducing the Provisional Crane Operator Knowledge Base Page

BC Crane Safety has launched a dedicated Provisional Crane Operator knowledge base page to support employers, supervisors and provisional crane operators in understanding their roles and responsibilities under B.C.’s regulatory framework.

In British Columbia, all crane operators must be certified in accordance with the WorkSafeBC Occupational Health and Safety Regulation, Section 14.34.1. As outlined in WorkSafeBC Guideline G14.34.1, crane operator certification is administered exclusively through the BC Association for Crane Safety (BC Crane Safety). This includes managing the application and assessment process, maintaining certification standards and issuing certifications.

The Provisional Crane Operator knowledge base page provides information on:

- getting started on a crane operator career in B.C. and the Yukon by completing the mandatory registration with BC Crane Safety and exploring provisional certification. Provisional designation is available for crane operators in training so that they can gain the competencies needed to become full scope operators.

- the responsibilities of employers, supervisors, and provisional operators when working with a provisional designation.

- the different certification types for a crane operator and how to apply for a provisional certification exam through our certification partner Fulford Certification.

- resources that support operators working toward full scope certification including certification requirements which may include passing written theory exams and practical assessments.

Visit the Provisional Crane Operator knowledge base page to access resources and get answers to your questions.

Evaluating Tower Crane Operator Competency

Ensuring tower crane operators are competent is not just a regulatory requirement, it’s a life-saving necessity. WorkSafeBC mandates that operators be certified under the OHS Regulation 14.34, with BC Crane Safety administering the certification process to uphold rigorous safety standards.

BC Crane Safety’s competency assessment system for employers:

- meets OHS & Workers’ Compensation Act requirements through documented evaluations.

- embeds safety into daily operations by tracking progress and addressing gaps.

- fosters a culture of shared responsibility, reducing accidents and improving productivity.

Specifically for tower cranes, WorkSafeBC’s guide Evaluating the Competency Level of a Tower Crane Operator, provides a structured approach to assess operators across three levels:

- Basic Competency (Requires Guidance)

- Developing Competency (Minimal Guidance)

- Competent (Independent)

Key skill areas include:

- Safety Practices (compliance with regulations, hazard awareness)

- Crane Operation (pre-use inspections, load handling)

- Rigging (sling selection, inspection/rejection criteria)

- Communication (hand signals, radio use)

- Emergency Response (power line contact, rescue procedures)

Working at Heights in the Heat: Are You Prepared?

Crane operators and rigging crews often work in exposed environments—high above ground, in direct sunlight, with little natural shade. Heat stress is a growing risk, especially during B.C.’s increasingly hot summers. Preventing heat-related illness is not only a safety priority but also part of an employer’s due diligence under WorkSafeBC requirements.

The ANSI/ASSP A10.50 Standard for Heat Stress Management In Construction and Demolition Operations offers essential guidance for preventing heat-related illnesses on job sites. The standard outlines five key strategies: hazard assessment, worker acclimatization, symptom recognition, control implementation and comprehensive training.

Visit our Preventing Heat Stress knowledge base page for more information on how to protect you and your team from heat-related illnesses this summer.

Five Practical Tips to Prevent Heat Stress in Crane Operations

Plan for Heat Hazards

Assess site-specific heat risks for crane operators, riggers, and workers at height. Monitor weather conditions and establish safe work practices before the heat hits.

Acclimatize Your Crews

Gradually introduce workers, especially new or returning operators, to hot conditions. Acclimatization helps build tolerance and reduces the risk of heat illness.

Control Exposure

Use heat stress controls, including:

- scheduling crane lifts earlier in the day.

- providing shaded rest areas at ground level.

- supplying cool drinking water near crane access points.

- installing shade barriers or reflective materials where possible.

Recognize Warning Signs

Educate crane crews to watch for signs of heat stress such as fatigue, dizziness, confusion, heat cramps or heat stroke. Supervisors should check in regularly, especially during extended lifts or complex operations.

Train for Response

Ensure all workers know emergency procedures for heat illness—from stopping work to providing first aid and calling for help.

The Right to Participate in Health and Safety Activities in the Workplace

Continuing with our worker rights and responsibilities series in the BC Crane Safety newsletter, this article focuses on the right to participate in health and safety activities in the workplace.

Identifying and resolving workplace safety concerns is particularly important in high-risk sectors such as crane operations.

Part 2 Division 4 of the Workers’ Compensation Act, Section 21(2)(b)(i), under the General Duties of Employers states “every employer must ensure that the employer’s workers are made aware of all known or reasonably foreseeable health or safety hazards to which they are likely to be exposed by their work…”

Employers are required to allow workers to have input on steps to ensure health and safety in the workplace. Here are some examples of how you can be involved in the process:

- Consider taking on a role as the health and safety representative for the workplace or becoming a member of the Joint Occupational Health and Safety Committee (whichever is applicable depending on company size and regulatory requirements).

- Report to your supervisor any hazards, concerns, or suggestions for improvement you may have about your safety processes or procedures.

- Participate in inspections and/or investigations at your workplace.

It’s important to note that workers cannot be disciplined or fired for participating in health and safety activities. Workers are protected from prohibited action such as suspension or dismissal, demotion, reduction in wages, reprimand, etc., as outlined in the Workers’ Compensation Act and WorkSafeBC Regulation 3.13.

For more information on roles, rights and responsibilities in the crane industry, review previous articles and resource pages:

Refusing Unsafe Work, BC Crane Safety Newsletter Winter 2024

The Right to Know About Hazards in the Workplace, BC Crane Safety Newsletter Spring 2025

WorkSafeBC: Roles, Rights & Responsibilities

New Requirements When Obtaining Your Provisional Designation

When obtaining a provisional designation in British Columbia, applicants must meet new key entry requirements to promote safe lifting practices from day one.

Candidates must provide proof of rigging theory training when applying for provisional designation, ensuring new operators start their certification journey with a strong understanding of rigging safety and procedures.

Starting on August 1, 2025, to further strengthen and reinforce the rigging knowledge component, the crane operator provisional exam administered by Fulford will be expanded from 23 to 40 questions, with an increased focus on rigging-related content.

This change reflects an industry-wide emphasis on foundational rigging competency and supports safer crane operations across B.C.

Updated Eligibility Requirements When Challenging Tower Crane Standardized Level Exams

Tower crane operator apprentices now have updated eligibility requirements for challenging Standardized Level Exams (SLEs), as outlined in SkilledTradesBC’s Official Program Standards Notification (OPSN): OPSN 2025 010: Tower Cranes.

To challenge Level 1, apprentices must complete 900 work-based training hours, including 500 hours operating a tower crane with a minimum mast height of 90 ft.

To challenge Level 2, 1,800 hours are required, with 1,000 hours of crane operation and 500 hours of documented rigging time.

To apply for the exam, a completed Tower Crane Operator Level Placement Exam Application Form must be submitted to SkilledTradesBC customer service.

You can review SkilledTradesBC OPSNs on their Program Standards Updates page.

Visit the SkilledTradesBC Tower Crane Operator trade page for more information including their program profile and exam application form.

Q&A

Question: I am seeking some clarification about whether an engineer is required for lifts involving persons in a work platform suspended from a mobile crane, e.g. A 65 ton, all terrain? Over water in B.C.?

Answer: The use of a mobile crane to lift personnel in a work platform (often referred to as a “man basket”) is subject to strict safety regulations. The requirement for an engineer’s involvement depends on the specific circumstances.

An engineer may be required to design or certify the work platform. OHSR Section 13.27(2) states that “If a work platform attached to a crane boom causes eccentric loading on the boom, the effect on the rated capacity of the crane must be determined and certified by the crane manufacturer or a professional engineer.”

If the lift involves unique or complex conditions (e.g., over water), it is a critical lift, which requires a written lift plan. See OHSR 14.42.1 Critical lift (1) “A written lift plan must be prepared for every critical lift and must be available at the worksite during the lift.”

Lifting personnel over water adds additional risks, such as the potential for drowning or difficulty in rescue operations. See OHSR 32.3 Equipment and note that a detailed risk assessment and safety plan are essential, and an engineer may be required to evaluate the stability and safety of the crane and platform under these conditions. Please see OHSR 32.9 Work areas over water.

Question: If a site asks me to load/unload a semi-truck on a busy road without closing the lane next to it, is it safe to operate?

Answer: WorkSafeBC and BC Ministry of Transportation regulations require proper traffic control when work affects roadways. OHS Regulations state employers must ensure a safe work environment, including protecting workers and the public from struck-by hazards.

If vehicles are moving adjacent to your crane during lifts, it introduces significant risks (swinging loads, equipment failure, distracted drivers, etc.). Under WorkSafeBC’s Occupational Health and Safety Regulation Section 3.12, you have the right to refuse work you believe is unsafe. If the site cannot provide proper traffic control (lane closure, barriers, or a spotter), the lift should not proceed until hazards are mitigated.

As outlined in OHSR 14.38(2) and (6), safe lifting referring to the load being handled safely and operating in proximity to other work activity would be relatable to the work described in addition to refusing what the operator feels is unsafe work.

Please report the unsafe condition to your supervisor as outlined in OHSR 3.10. If your concern is not investigated or mitigated, you can refuse to work and escalate the issue to WorkSafeBC.

Question: If test block rigging doesn’t go more than one foot off the ground on a daily basis, does it still have to be inspected annually?

Answer: WorkSafeBC Regulation 15.50 states “a chain sling must be thoroughly inspected at least once a year, and a record of the inspection must be kept.” There is no adjustment to this regulation based on the height the test block is lifted. These annual inspections must be documented and available for review whenever requested.

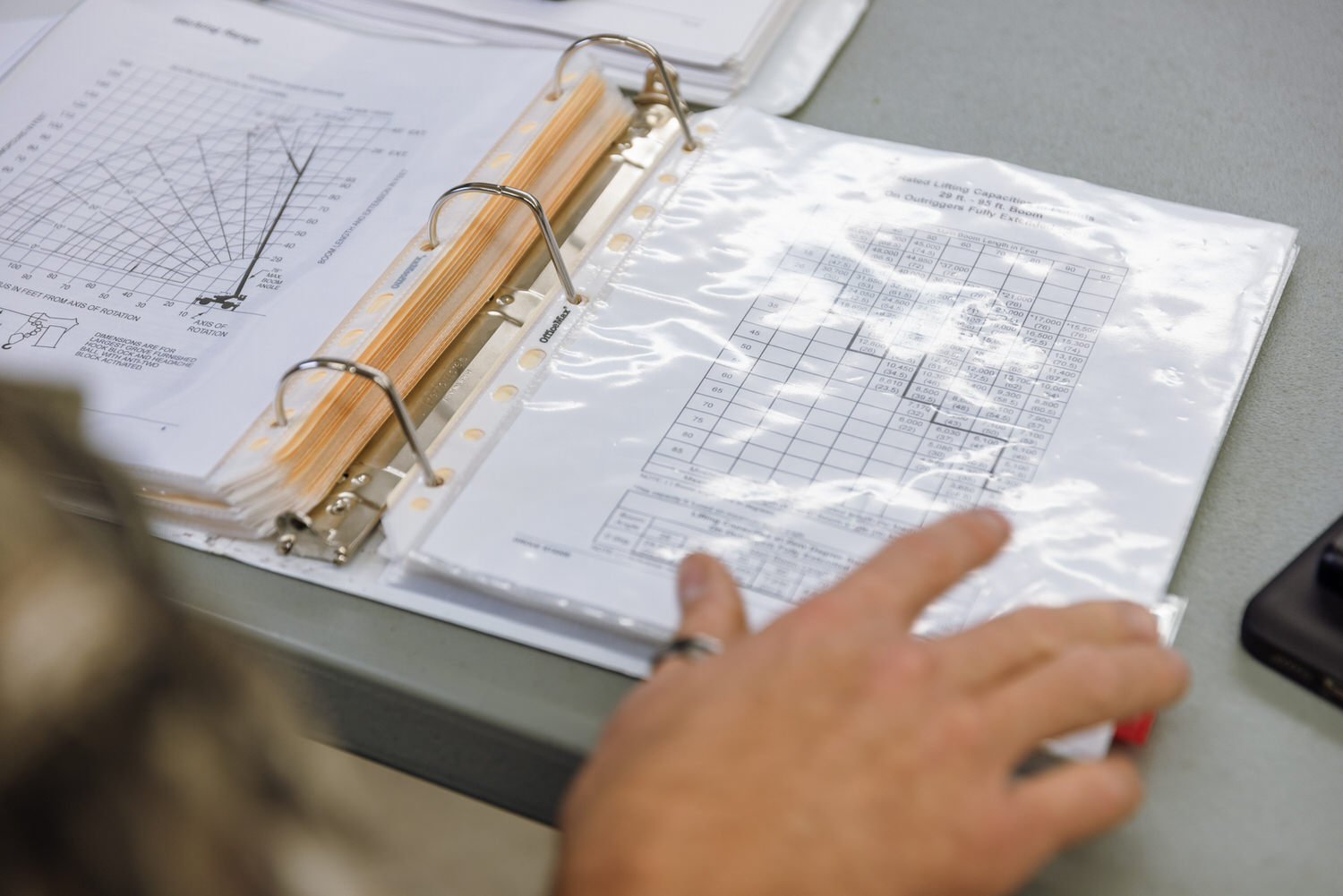

Question: Did you know that the Tower Crane Practical Assessment is changing on August 1, 2025?

Answer: Starting August 1, 2025, the Tower Crane Load Chart & Rigging exam will be reinstated as part of SkilledTradesBC’s practical assessment for Tower Crane Operators.

The Tower Crane Load Chart & Rigging Exam includes:

- 10 questions (8 questions based on tower crane load charts, 2 questions on rigging charts)

- All necessary reference materials, including crane load charts and jib rating charts, will be provided—no additional manuals or full load chart packages are required.

A minimum of 7 out of 10 correct answers is required to demonstrate competency and obtain a passing score, as mandated by B.C.’s crane industry.

If your Tower Crane Operator Practical Assessment is scheduled on or after August 1, 2025, you must successfully complete this exam component.

Fulford has published a guide for learning how to read load charts and practice questions to help you prepare for the exam.